In an era where environmental sustainability is imperative, the adoption of eco-friendly pumping solutions is crucial for industries and communities.

The negative environmental impact of traditional pumping technologies—marked by high energy consumption and carbon emissions—calls for a shift towards sustainable practices.

Tsurumi, a leader in pumping solutions, is at the forefront of this shift, pioneering innovations that meet fluid handling demands and contribute to environmental sustainability. Tsurumi’s commitment goes beyond functional excellence; it integrates advanced technologies with a dedication to reducing ecological footprints.

Through products like the Electrode Control Device and the energy-efficient KTVE series, Tsurumi underscores its dedication to energy efficiency, waste minimization, and extending pump longevity. These innovations reflect Tsurumi’s ethos: to provide pumping solutions that excel in performance and environmental stewardship.

As we explore Tsurumi’s eco-friendly pumping solutions, their commitment is clearly about setting new sustainability benchmarks in the pumping industry, not just meeting existing standards.

Tsurumi’s Approach to Environmental Sustainability

Electrode Control Device: Precision Automation for Enhanced Pump Efficiency

Automatic Operation Benefits

Tsurumi’s commitment to environmental sustainability is exemplified through its innovative Electrode Control Device, which embodies its approach to eco-friendly pumping solutions. This device is central to reducing power consumption and extending the operational lifespan of pumps.

Facilitating automatic operation ensures that pumps are active only when necessary, thereby conserving energy.

This intelligent functionality not only lowers operational costs but also significantly contributes to the longevity of the equipment, diminishing the frequency of replacements and repairs.

Environmental Benefits

The environmental benefits of this technology are profound. By minimizing the need for manufacturing new pumps or parts, Tsurumi’s approach effectively conserves resources and reduces the environmental footprint associated with production.

Additionally, the extended life expectancy of their pumps means fewer units are discarded, leading to a decrease in waste and a positive impact on waste management practices.

Technical Advantages

From a technical perspective, the Electrode Control Device offers crucial advantages. It prevents dry-running, a common issue that can cause severe internal damage to pumps, by automatically controlling their operation based on the water level.

This safeguards the pump and enhances its efficiency, as the device eliminates unnecessary energy expenditure. Moreover, compared to non-automatic pumps, this technology can save a significant amount of energy, thereby reducing CO2 emissions by approximately 40%.

This achievement is a testament to Tsurumi’s dedication to providing solutions that are not only effective but also environmentally responsible, aligning with global efforts to combat climate change and promote sustainability.

LB-A Series: Advanced Pumping Solutions with Electrode Control Technology

Innovative Automatic Control

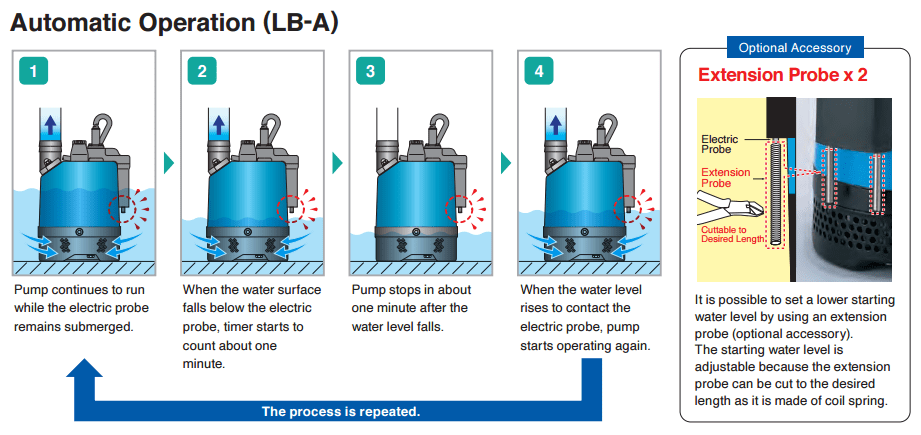

Tsurumi’s LB-A Series showcases its commitment to innovation with an automatic electrode control device. This advanced mechanism optimizes efficiency by preventing dry-running, protecting the pump from damage, and significantly conserving energy.

Energy Efficiency through Innovative Automatic Control

By reducing unnecessary operation, the LB-A Series cuts power consumption by up to 40% compared to non-automatic pumps, emphasizing Tsurumi’s focus on sustainable practices.

The device also addresses chattering from turbulent waters, enhancing operation smoothness and extending the pump’s lifespan. This boosts efficiency and supports environmental sustainability by lessening the need for frequent pump replacements.

Float Switches: Enhancing Pump Performance and Reliability

Functionality

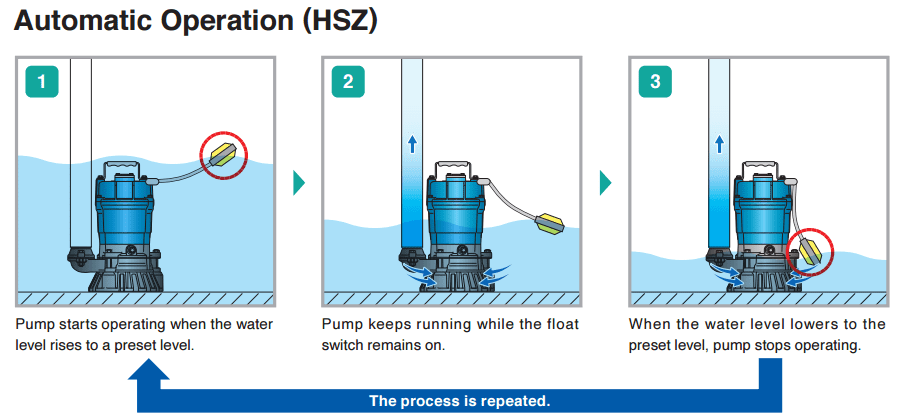

Float switches serve as critical components in the efficient management of liquid levels within various systems. These devices act as liquid-level sensors, meticulously monitoring the rise and fall of liquid within a sump or environment.

The fundamental role of float switches is to ensure that pumps operate at optimal times based on the specific needs of the system they serve. By detecting the level of liquid, float switches can initiate or halt the operation of pumps, thereby preventing issues such as overflow or dry running.

Operational Efficiency

The integration of float switches significantly enhances the operational efficiency of pump systems. These devices automate the start and stop process of pumps according to the liquid level, eliminating the need for manual intervention.

When the liquid level reaches a predetermined high point, the float switch activates the pump, allowing it to start moving liquid. Conversely, as the liquid level decreases to a set low end, the float switch deactivates the pump, halting its operation.

This automated process ensures pumps run only when necessary, optimizing energy usage and reducing wear and tear on the pump’s components.

Through the strategic use of float switches, pump systems achieve greater reliability and longevity, contributing to overall operational efficiency and sustainability.

Automatic Pump Range for CO2 Emission Reduction

Tsurumi’s dedication to environmental sustainability is further demonstrated through its range of automatic pumps designed to reduce CO2 emissions. Each model in this range contributes to energy efficiency and sustainability in unique ways:

- KTVE: Integrates advanced electrode control for reduced energy consumption and enhanced operational efficiency.

- KRS: Features a low-output and low-head design, optimizing energy use for heavy-duty drainage applications.

- PUA & PUW (Auto-Alternation model): Offers innovative alternation operation, ensuring balanced usage and energy savings across multiple pumps.

- PNA & PNW (Auto-Alternation model): Utilizes auto-alternation to extend pump life and reduce energy usage, suitable for various water applications.

- TMA: Tailored for tough mining applications, combining durability with energy-efficient performance.

- LB-A: Showcases Tsurumi’s unique automatic control via electrodes, significantly cutting down on power use.

- HSZ: Designed for high-efficiency and automated water level control, reducing energy costs and CO2 emissions.

Each model in Tsurumi’s automatic pump range is a testament to the company’s commitment to providing sustainable pumping solutions that meet the needs of modern industries while protecting the environment.

KRS (Energy-Saving) Series Pump: A Paradigm of Efficiency and Durability

Design and Efficiency

The KRS (Energy-Saving) series pump is engineered as a drainage pump focusing on low output and head to ensure reduced power consumption.

This thoughtful design caters to the need for energy efficiency in pumping operations, making it an ideal solution for environmentally conscious applications.

The low output and head specification of the KRS series directly contributes to its ability to minimize energy use without compromising performance, offering a sustainable option for drainage needs.

Durability Features

In addition to its energy-saving design, the KRS series boasts exceptional durability. Constructed with a three-phase cast iron body, the pump is designed to handle high volumes, making it a heavy-duty solution capable of withstanding the most challenging conditions.

The robust cast iron body, paired with a low-speed motor, enhances the pump’s longevity, ensuring it remains a reliable drainage system component. This combination of durability and efficiency underscores Tsurumi’s commitment to offering products that are energy-efficient and built to last.

KTVE Series Pump: Revolutionizing Efficiency with Electrode Control

Electrode Control Device

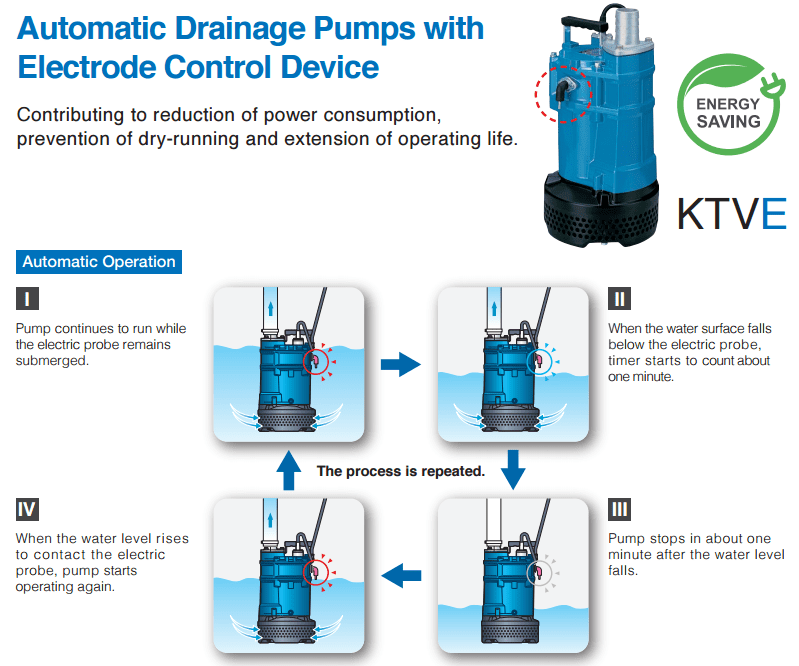

The KTVE series pump from Tsurumi introduces a groundbreaking advancement in pumping technology with its Electrode Control Device. This unique automatic control system utilizes an electrode, incorporating an electric probe and relay unit designed to optimize pump operation.

When the water level makes contact with the electric probe, it establishes electric continuity between the electrode and the pump body, prompting the relay unit to activate the pump.

This system includes a timer function, ensuring the pump ceases operation approximately one minute after the water level falls below the probe. Should the water level reach the probe again within the run time, the pump resumes operation for an additional minute.

This innovative approach enhances operational efficiency and significantly extends the pump’s lifespan by preventing dry-running and the potential damage it can cause.

Energy Savings and Operational Benefits

According to Tsurumi’s comparisons, one of the most notable advantages of the KTVE series pump is its ability to reduce power consumption by up to 40% compared to non-automatic pumps.

This substantial energy saving is achieved by eliminating dry-running and the pump’s ability to adjust to varying water levels without manual intervention.

Additionally, the system’s design counters the effects of chattering caused by turbulent water surfaces, further extending the operational life of the pump.

The option to adjust the starting water level with an extension probe—an optional accessory—allows for even greater control and efficiency.

By cutting the extension probe to the desired length, users can tailor the pump’s activation to specific conditions, optimizing energy use and enhancing the overall sustainability of the operation.

Video Resource

Conclusion

Tsurumi’s dedication to innovation and environmental sustainability in pumping technology has significantly reduced power consumption and CO2 emissions.

Their advanced solutions, such as the Electrode Control Device and the energy-efficient KRS series, highlight Tsurumi’s commitment to ecological stewardship.

The introduction of the LB-A and KTVE series underscores the importance of sustainable practices in the industry, setting new standards for environmental responsibility.

This advancement serves as a call to action, urging the adoption of green pumping technologies to foster a more sustainable future. By choosing energy-efficient and environmentally conscious solutions, we contribute to global sustainability efforts.