Welcome to Tsurumi Australia – Your Guide to Optimising Submersible Pump Performance

Submersible pumps are essential for a wide range of applications, from wastewater management to groundwater extraction and beyond. At Tsurumi Australia, we understand that choosing the right pump is just the beginning.

Submersible pumps are essential for a wide range of applications, from wastewater management to groundwater extraction and beyond. At Tsurumi Australia, we understand that choosing the right pump is just the beginning.

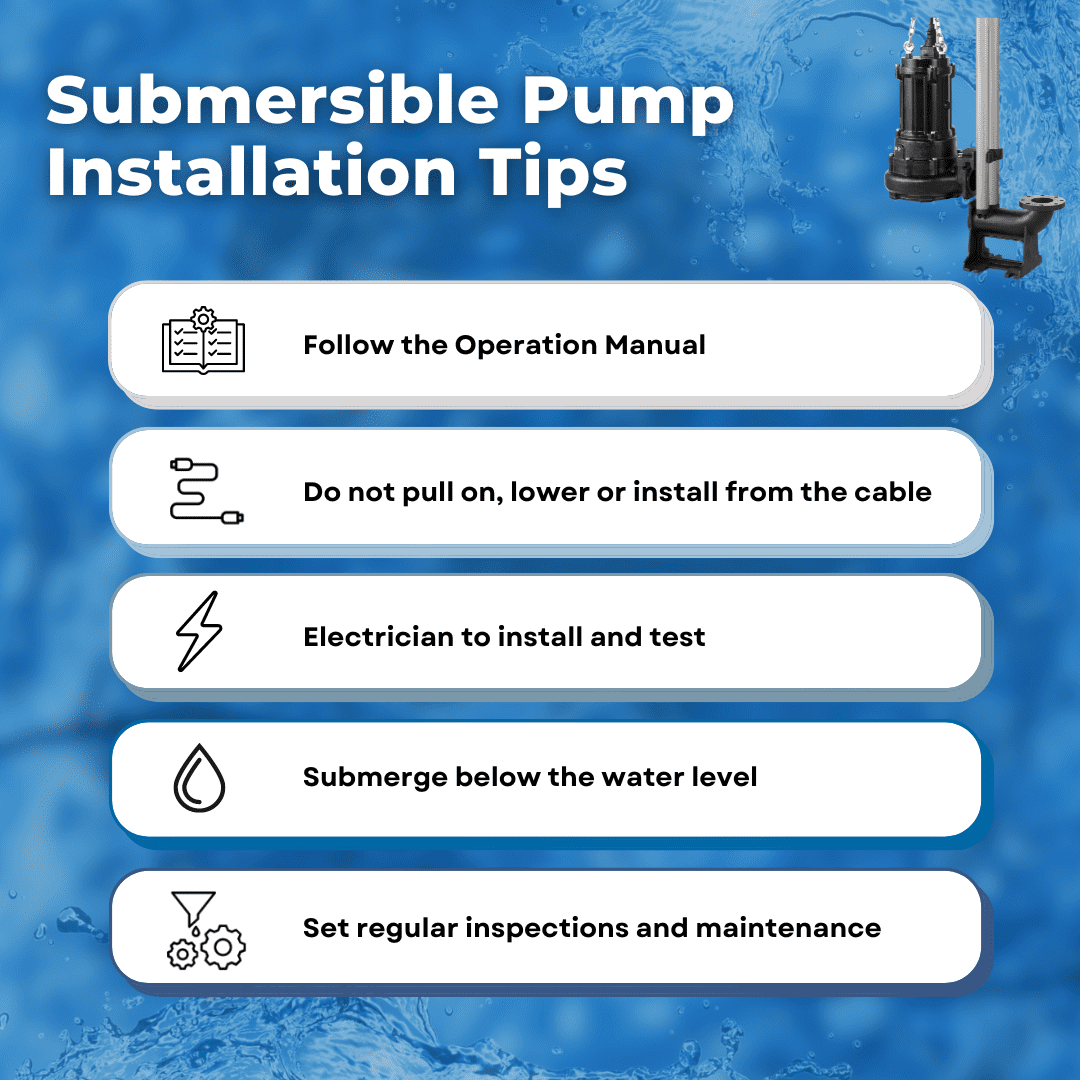

Proper installation is key to ensuring your pump delivers reliable, efficient performance throughout its lifespan. In this guide, we’ll explore the critical role of correct installation practices.

A well-installed submersible pump not only enhances performance but also extends the life of your equipment, reducing downtime and maintenance costs. However, improper installation can lead to costly issues such as reduced efficiency, frequent repairs, and potential equipment failure.

Discover the best practices for installing submersible pumps and learn how to maximize their effectiveness in your operations. With our expertise and commitment to quality, we’re here to support you every step of the way.

Pre-Installation Preparation: Setting the Stage for Longevity

Before installing your submersible pump, a thorough pre-installation check is essential to ensure smooth operation and avoid potential issues down the line. At Tsurumi Australia, we believe that a little preparation goes a long way in safeguarding the performance and longevity of your pump.

Inspecting the Pump Before Installation

Begin by inspecting your pump carefully for any signs of damage that may have occurred during transport. Even minor damage can affect performance, so it’s crucial to address any issues before proceeding with the installation.

Next, check all bolts and nuts to ensure they are tightened properly. Loose components can lead to operational inefficiencies and potential safety hazards. A quick inspection and adjustment at this stage can prevent problems later on.

Finally, confirm that you have the correct pump model, voltage, and power frequency for your specific application. Ensuring the right specifications from the start helps avoid costly errors and ensures your pump is ready to perform at its best.

By taking these steps before installation, you’re setting your submersible pump up for reliable, efficient operation from day one.

Necessary Tools and Equipment: Preparing for a Safe and Accurate Installation

Having the right tools on hand is crucial for safely and precisely installing your submersible pump. Proper preparation not only streamlines the installation process but also ensures that the pump operates efficiently and safely.

At Tsurumi Australia, we recommend equipping yourself with the following essential tools:

- Insulation Resistance Tester: Vital for checking the electrical insulation of the pump motor and cables, ensuring there are no leaks or faults before powering up.

- AC Voltmeter: Used to verify the voltage levels match the pump’s requirements, safeguarding against incorrect power supply connections.

- AC Ammeter (Clamp-on Type): Allows for non-invasive current measurement, helping to confirm that the pump is drawing the correct amount of current during operation.

- Bolt and Nut Tighteners: Ensure all fasteners are secured correctly, maintaining the pump’s structural integrity and preventing leaks or operational failures.

- Power Supply Connection Tools (Screwdriver or Box Wrench): Essential for making accurate and secure electrical connections.

Having these tools ready and in good working condition is key to achieving a precise installation, minimising risks, and ensuring the pump performs reliably from the start.

Safety Precautions During Installation: Protecting Your Investment

Safety is paramount when installing submersible pumps, and proper handling practices are essential to ensure both the longevity of your equipment and the safety of your team.

At Tsurumi Australia, we emphasize the importance of following recommended safety precautions to prevent avoidable damage and risks

Handling the Pump Safely

When moving or positioning your pump, always use the designated handles or eye bolts. These are specifically designed to support the weight and structure of the pump, allowing for safe and controlled handling.

Never use the electrical cable to lift, lower, or move the pump. Pulling on the cable can cause serious damage, including electrical leakage, short circuits, or even fires, and will void your warranty.

Improper handling not only compromises the pump’s performance but also poses significant safety hazards such as electrical shock or equipment failure.

By adhering to correct handling procedures, you’re not just protecting your investment—you’re ensuring a safe work environment for everyone involved.

Electrical Safety Measures

Electrical safety is a critical aspect of submersible pump installation, and taking the right precautions can make all the difference in performance and safety.

Before making any electrical connections, always ensure the power supply is completely turned off to prevent accidental shocks or electrical hazards.

Proper grounding of the pump is equally essential—it helps protect against electrical shocks, prevents malfunctions, and ensures the pump operates as intended.

At Tsurumi Australia, we strongly recommend adhering to all relevant Australian electrical standards and guidelines when wiring and grounding your pump.

Following these standards not only ensures compliance but also safeguards the integrity of your installation, providing peace of mind that your system is both safe and efficient.

Step-by-Step Installation Guide: Getting Your Pump Up and Running

Proper installation of your submersible pump is crucial for optimal performance and longevity. Follow these step-by-step instructions to ensure a safe and effective setup:

Proper installation of your submersible pump is crucial for optimal performance and longevity. Follow these step-by-step instructions to ensure a safe and effective setup:

Step 1: Positioning the Pump

- Begin by positioning your pump in the desired location, ensuring it is fully submerged below the water level. This is essential for the pump to operate correctly and avoid overheating.

- Lower the pump carefully using handles or eye bolts. Avoid pulling or dragging the pump by its cables, as this can cause kinks, damage, or electrical faults.

Step 2: Connecting the Electrical Components

- Connect the electrical cables securely to the control box (if applicable) following the manufacturer’s instructions. Ensure all connections are made according to the pump’s specifications.

- Use waterproof connectors to protect against moisture and ensure proper insulation of all connections. This helps prevent electrical leaks and ensures safe operation.

- Double-check that all connections are tight and secure before proceeding.

Step 3: Piping and Connections

- Select piping that is appropriate for your specific application, considering factors like corrosion resistance, pressure rating, and fluid compatibility.

- Ensure proper pipe sizing, and alignment, and secure all connections tightly to avoid leaks and unnecessary stress on the pump.

- If required, install a check valve on the discharge pipe to prevent water from flowing back into the system, which can help maintain optimal pump performance.

Testing and Initial Operation

Electrical Testing

Before putting your submersible pump into full operation, it’s crucial to conduct thorough electrical testing to ensure everything is functioning correctly. Start by using a megohmmeter to test the motor’s insulation resistance.

This step helps identify any potential issues with the motor insulation, preventing faults that could lead to equipment failure or unsafe operation. Next, verify that all wire connections are secure and correct, ensuring there are no loose ends that could affect performance.

Check the motor direction rotation to confirm it matches the pump’s specifications, as incorrect rotation can compromise efficiency and cause damage.

Priming and Starting the Pump

Priming your submersible pump, if applicable to your pump type, is a vital step to ensure it operates efficiently from the start. Priming removes air from the system, allowing for a smooth flow of water and preventing air locks that can disrupt performance.

It’s crucial to follow the manufacturer’s specific priming methods to prepare the pump correctly. Once primed, proceed with the start-up procedures outlined in the manufacturer’s guidelines, taking care to monitor the pump closely during the initial operation.

Watch for any abnormal noises, vibrations, or performance issues that might indicate an underlying problem.

Performance Monitoring

Once your submersible pump is up and running, ongoing performance monitoring is essential to maintain its efficiency and longevity. Regularly check the water flow and pressure to ensure the pump is operating within its specified parameters.

Keep an ear out for any unusual noises, such as rattling or grinding, which could indicate mechanical issues or blockages. Early detection of irregularities allows for prompt action, preventing minor issues from escalating into costly repairs.

If you notice any signs of reduced performance or suspect a problem, consult the troubleshooting guide provided by the manufacturer or seek professional assistance.

Post-Installation Tips

Proper maintenance is the key to extending the life of your submersible pump and ensuring it continues to operate at peak efficiency. Here are some essential tips to keep your pump in top condition:

- Set Regular Reminders for Inspections: Schedule routine inspections and maintenance checks to stay ahead of potential issues. Regular inspections help identify wear and tear early, preventing minor problems from developing into major failures.

- Check for Debris and Blockages: Regularly inspect the pump, impeller and intake for any debris or blockages that could affect performance. Clearing these promptly helps maintain optimal flow and reduces strain on the pump.

- Inspect Electrical Connections: Periodically check all electrical connections for signs of corrosion, looseness, or damage. Secure connections are critical to avoiding electrical faults and maintaining safe operation.

- Monitor Seal Integrity: Inspect the pump seals for any signs of wear or leakage. Replacing worn seals early can prevent water ingress that might damage the motor or other internal components.

- Lubricate Moving Parts as Needed: Ensure that any moving parts are adequately lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction and wear, enhancing the overall efficiency of the pump.

- Test Performance Parameters: Routinely check the pump’s performance parameters, such as flow rate and pressure, to ensure they remain within the specified range. Any deviation could indicate underlying issues that need attention.

By following these post-installation tips, you can maintain the reliability and efficiency of your submersible pump, ensuring it continues to perform when you need it most.

Partner with Tsurumi Australia for Expert Submersible Pump Installation and Support

Ensure your submersible pump delivers the performance, efficiency, and reliability you need with Tsurumi Australia by your side. From choosing the right pump to ensuring it’s installed correctly, our team of experts is here to support you every step of the way.

Explore our range of high-quality submersible pumps and let us guide you through the best practices for installation and maintenance.

Contact Tsurumi today to learn how our tailored solutions and dedicated customer service can help you achieve optimal results in any application. Trust Tsurumi—Australia’s leading choice for dependable pump solutions.