World-leading Japanese

pumps available in Australia

World-leading Japanese pumps available in Australia

Shop online

Better access to single-phase pumps, parts & accessories – buy online now!

Welcome to Tsurumi Australia

Tsurumi Australia is part of the global Tsurumi Pump network which began in Japan in 1924. We represent one of the highest quality and longevity products in the industry. We work closely with our distributors and customers to provide an ultimate pumping solution to keep operations flowing smoothly. We don’t just provide you a submersible pump, we ensure customers are given the kind of individual attention, support and consultation they need, when they need it.

Key Industries

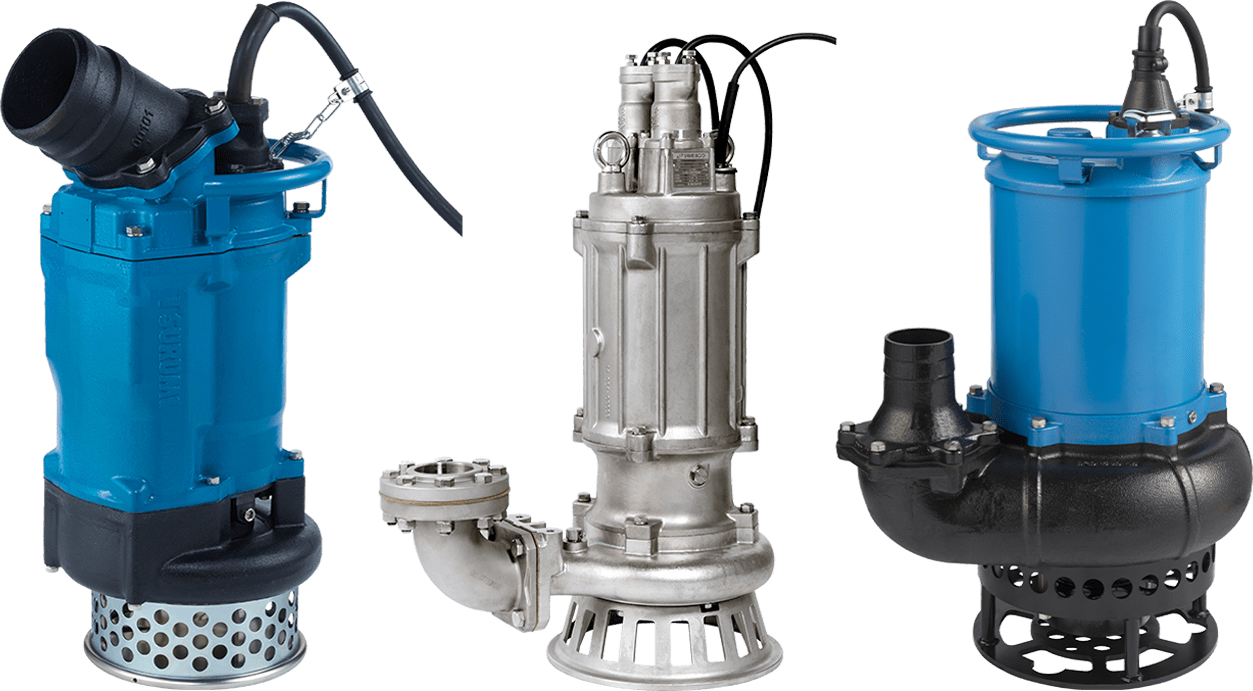

Tsurumi Pump Australia specializes in high-quality submersible pumping solutions used across various industries, including civil engineering, construction, mining, sewage & wastewater, and water treatment. Their submersible pumps are renowned for reliability and are utilized in applications such as tunnels, bridges, dams, infrastructure projects, temporary sewage bypasses, and rainwater drainage to prevent flooding.

Tsurumi Pumps

Are Built To Last

Tsurumi introduced its overseas strategy in the 1960s. Our technical capabilities gained recognition first Asia in the 1970s and then in the United States and Europe in the 1980s. Following these initial successes, we sought to accelerate the overseas strategy through our International Sales Division. Remarkable successes in fields including construction, civil engineering, mining, industrial wastewater, domestic wastewater, sewage treatment, flood control, facilities designed to bring people into closer contact with water, and scenery creation have proven Tsurumi’s creativity and capability to the world.

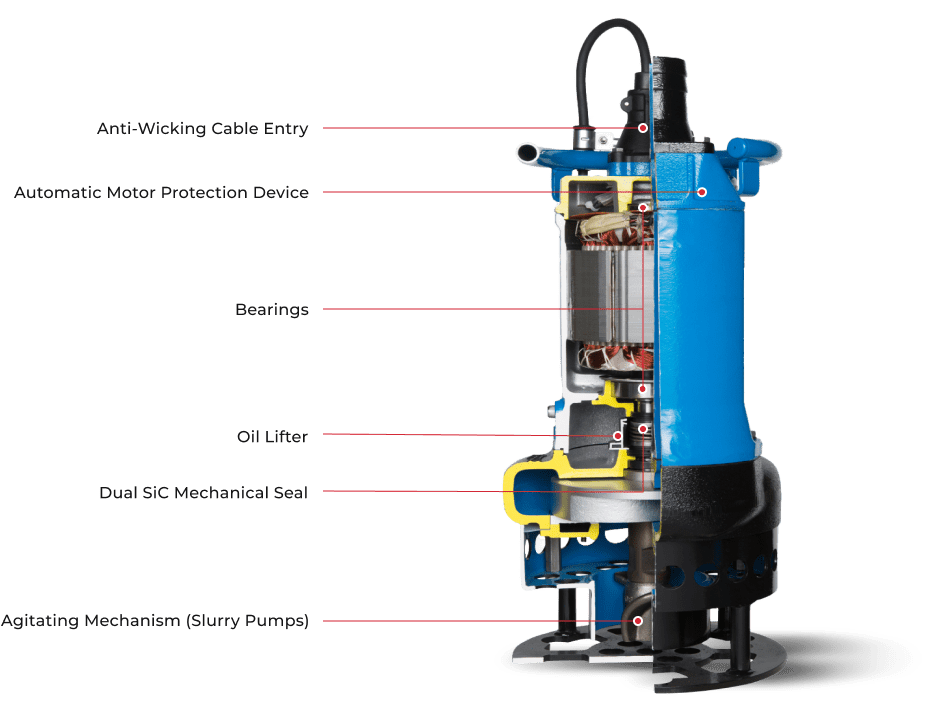

Main Features and Benefits

Tsurumi’s submersible pumps come loaded with proprietary technologies that are tested and proven over the years. In addition, for the sake of durability, wear-resistant materials are adopted for parts that tend to wear down more easily which pave the way for continuous duty over extended periods of time.

Anti-Wicking Cable Entry

An anti-wicking block is provided at the cable entry section of the motor chamber. Even if the cable jacket becomes damaged or the tip of the cable is accidentally immersed in water, this device prevents water from traveling into the motor chamber through capillary action.

Oil Lifter

The Oil Lifter was developed as a lubricating device for the mechanical seal. Utilizing the centrifugal force of the shaft seal, the Oil Lifter forcibly supplies lubricating oil to the upper seal faces even if the lubricant falls below the specified volume. This amazingly simple device reliably lubricates and cools but also stabilizes the effect of the shaft seal and extends the length of the inspection period.

Dual SiC Mechanical Seal

A dual inside mechanical seal, located in the oil chamber together with the Oil Lifter, has two sealing faces made of quality materials, including silicon carbide (SiC). The advantages of this seal are two-fold; it eliminates spring failure caused by corrosion, abrasion or fouling, which can prevent the seal faces from closing properly, and prevents loss of cooling to the lower seal faces during run-dry conditions, which causes the lower seal faces to fail.

Automatic Motor Protection Device

A built-in thermal motor protection device reacts to the excessive heat caused by overcurrent or run-dry conditions. It not only cuts off the motor circuit automatically but also resets by itself.

Bearings

High-grade bearings for high-temperature operation are used. Also, as deep-groove, double-shield ball bearings are used, and as the bearings are permanently lubricated by grease, there is no need for injection of lubricating oil.

Agitator Mechanism (Slurry Pumps)

Slurry pumps are installed with an agitator on the motor shaft extension which forcibly agitates the fluid for easy and efficient transfer of slurry, sand, mud or other particulates. The high-chromium cast iron agitator resists wear caused by abrasive particles and assists with smooth suction of the settled matters.

Featured Products

Tsurumi has been leading the market in innovative designs for over 100 years.

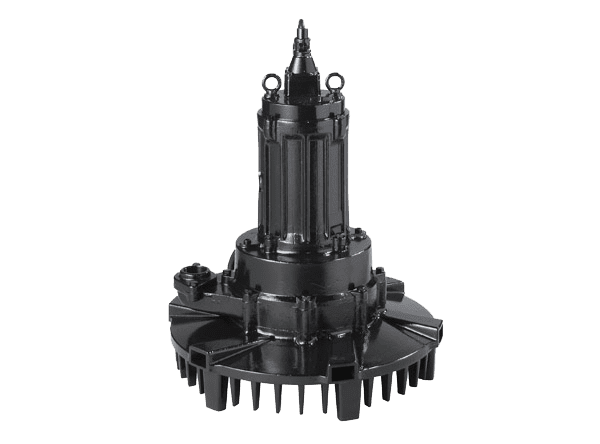

The TRN-series is a submersible self-aspirating aerator designed for aeration and mixing of wastewater. The liquid flow generated by Tsurumi’s special semi-open impeller causes negative pressure to form on the backside of the impeller vanes and draw in air from above the water’s surface.