Welcome to Tsurumi Australia’s comprehensive guide on submersible pumps – essential information for a wide range of applications.

Whether you’re managing wastewater, dewatering a construction site, or simply keeping water flowing in various settings, submersible pumps are designed to deliver reliable performance across various industries.

From industrial and municipal projects to construction and mine sites, these pumps are vital in ensuring efficient and smooth operations.

Selecting the right type of submersible pump is crucial for maximising efficiency, reducing maintenance, and ensuring long-term performance tailored to your specific application.

Types of Submersible Pumps

#1 Dewatering Pumps

#1 Dewatering Pumps

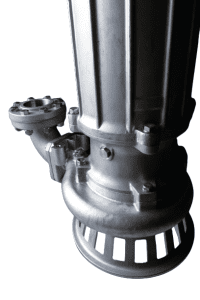

Dewatering pumps (submersible water pumps) are essential for removing groundwater or surface water from construction sites, mines, quarries, and other locations where water needs to be managed efficiently. Their main purpose is to ensure dry and stable conditions for safe excavation and operations.

Commonly used in construction, mining, and areas prone to flooding or stormwater runoff, submersible dewatering pumps transport water to drainage pits or a septic tank for removal.

At Tsurumi Australia, we offer reliable series like the KTZ(E), KRS, KTV, LH, LSC and LB(A), each designed for powerful performance in challenging environments. Proper groundwater removal reduces downtime, making these pumps critical in many industries.

#2 Drainage Pumps

#2 Drainage Pumps

Drainage pumps are designed to move water from one area to another, making them ideal for low-lying locations where water collects. They are commonly used in basements, swimming pools, sump pits, housing and construction sites, wastewater and agricultural settings.

Tsurumi Australia’s range are efficient at removing both clean water and dirty water mixed with light abrasives.

These pumps are versatile and suitable for both commercial and residential use, providing dependable solutions for a wide range of water-moving needs.

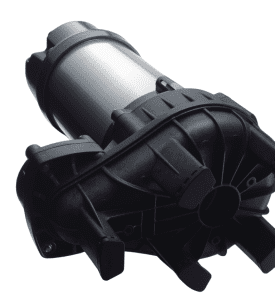

#3 Grinder & Cutter Pumps

Grinder and cutter pumps are specialized for handling solids in wastewater; they can also be used at food processing plants and abattoirs. Tsurumi Australia offers series llike the BZ, C, CZ and MG. Grinder pumps process soft solids, like sewage, by grinding them into a slurry for easier transport, making them ideal for municipal sewage systems, basements, and shopping centres.

Cutter pumps, on the other hand, are designed to cut larger, harder solids into smaller pieces for more efficient pumping; commonly used for industrial waste, raw sewage, and wastewater systems.

The main difference is that grinder pumps are low-volume, high-pressure systems for soft solids, while cutter pumps handle flushable materials, reducing the risk of clogging.

#4 Sewage & Wastewater Pumps

#4 Sewage & Wastewater Pumps

Sewage and submersible wastewater pumps are specifically designed to handle raw sewage and wastewater with varying particle sizes. These pumps are essential in domestic, municipal, and industrial sewage systems, as well as wastewater treatment plants.

Tsurumi Australia’s range includes series like the U, CZ, BZ, SF, VANCS, and KRSU, each built to manage the tough demands of sewage transport.

These pumps move wastewater through treatment systems and are often equipped with grinders or cutters to handle solids efficiently, ensuring smooth operation and preventing blockages.

#5 Slurry Pumps

#5 Slurry Pumps

Slurry pumps are specifically designed to handle liquids mixed with solid particles, making them ideal for challenging environments. These pumps are commonly used in mining, steel processing, dredging, and concrete plants.

Tsurumi Australia’s series, such as the HSD, GPN, GSD, KTD, KTV and GSZ, are built to manage solid material in fluids. Slurry pumps often include agitators that assist in the suction and transfer of materials like mud, cement, manure and bentonite slurry, ensuring efficient operation even in heavy-duty conditions.

#6 Stainless Steel Pumps

#6 Stainless Steel Pumps

Stainless steel submersible pumps are built from corrosion-resistant materials, making them perfect for handling acidic and aggressive environments. These pumps are commonly used in chemical processing, wastewater management, and water treatment applications.

Tsurumi Australia’s submersible stainless steel pump series, such as the VANCS, SFQ, GSD, LH, and SQ, offer excellent durability and performance. The high corrosion resistance ensures a longer lifespan, while also reducing maintenance costs in harsh, corrosive conditions, making them a reliable choice for demanding industrial environments.

Choosing the Right Submersible Pump

Key Factors to Consider

When selecting the right submersible pump for your needs, it’s essential to consider several key factors that will help ensure optimal performance and durability. Here are the main considerations to keep in mind:

- Type of fluid to be handled: It’s crucial to choose a pump body based on whether you’ll be moving clean water, wastewater, or slurry, as different pumps are designed to manage various fluid types efficiently.

- Solid content in the fluid: The presence of solids in the fluid can significantly impact a pump’s performance. You’ll need a pump that can effectively handle the size and quantity of particles without clogging or reducing efficiency.

- Pump material for corrosive or abrasive fluids: If you’re working in environments with harsh chemicals or abrasive materials, selecting a pump made from corrosion-resistant materials, like stainless steel, will help ensure longevity and reduce wear and tear.

- Operational needs such as pressure, flow rate, and volume: The pump’s operational requirements, including the desired pressure, flow rate, and volume, should align with your specific application to ensure smooth and reliable performance over time.

Tsurumi Pump Selection Guide

The Tsurumi Pump Selection Guide is designed to help you choose the ideal pump for your specific project needs. By matching the right pump type with your application, you can ensure efficient, reliable performance in any environment:

- Dewatering pumps are perfect for temporary water removal on construction sites, mines, and other areas where groundwater needs to be managed quickly and effectively.

- Drainage pumps are suited for regular water transfer, making them ideal for moving water from sump pits, basements, or low-lying areas.

- Grinder or cutter pumps are designed for waste management, handling solids efficiently by grinding or cutting them to prevent clogs in sewage or wastewater systems.

- Slurry pumps are built to handle fluids with high solid content, making them ideal for industries like mining, steel processing, and dredging where thick mixtures need to be moved.

- Stainless steel pumps are the best choice for corrosive environments, providing long-lasting durability and resistance to aggressive chemicals and abrasive materials.

- Residue pumps are perfect for removing residual water left from dewatering or drainage pumps, making them ideal for use in construction sites or flooded areas.

By selecting the right pump for your project, you’ll maximise efficiency and ensure reliable performance for years to come.

Partner with Tsurumi Australia for Expert Guidance on Understanding Different Types of Submersible Pumps

Understanding the various types of submersible pumps is essential for achieving efficiency, reliability, and long-term performance. At Tsurumi Australia, we offer a range of high-quality pumps to meet diverse needs, from dewatering and drainage to wastewater, slurry, and corrosive environments.

Explore our selection of submersible pumps and let our expert team help you choose the right pump for your application.

Contact Tsurumi today to discover how our expertise and tailored solutions can deliver optimal results. Trust Tsurumi—Australia’s top choice for dependable pump solutions.

#1 Dewatering Pumps

#1 Dewatering Pumps #2 Drainage Pumps

#2 Drainage Pumps #4 Sewage & Wastewater Pumps

#4 Sewage & Wastewater Pumps #5 Slurry Pumps

#5 Slurry Pumps #6 Stainless Steel Pumps

#6 Stainless Steel Pumps