Submersible pumps play a vital role across various industries, offering reliable solutions for managing water and other fluids in challenging environments.

Designed for operating while fully submerged, these pumps are integral to construction, mining, industrial, and wastewater management applications.

Selecting the right submersible pump—manual or automatic—is crucial for optimising efficiency, reducing maintenance requirements, and controlling operational costs. Each type has unique advantages, catering to specific needs based on fluid levels, frequency of use, and site demands.

In this guide, we’ll look into the differences between manual and automatic submersible pumps, helping you understand their functionality and applications to make an informed choice.

What is a Manual Pump?

A manual submersible pump is a straightforward and dependable solution for fluid management, designed to operate through direct human intervention. Unlike automatic models, manual pumps require the user to physically plug them in to start operation and unplug them to stop; or controlled via a control panel.

This simple mechanism makes them a practical choice for situations where water levels or pumping needs are inconsistent, allowing users full control over when and how the pump is used.

Common Use Cases for Manual Pumps

Manual submersible pumps are best suited for scenarios where flexibility and simplicity are key. Here are some common use cases:

Inconsistent Fluid Levels

Manual submersible pumps are an excellent choice for situations where water levels fluctuate or are unpredictable. These pumps allow users to manage fluid levels as needed, providing flexibility and direct control over their operation.

This makes them particularly suitable for applications where pumping requirements are irregular, such as emergency drainage or seasonal use. By relying on manual intervention, users can adapt the pump’s operation to changing conditions with ease.

Cost Considerations

One of the main advantages of manual pumps is their lower upfront cost compared to automatic pumps models. This affordability makes them an appealing option for budget-conscious projects or temporary applications.

However, if a manual pump needs to be connected to a control panel for more sophisticated operation, additional installation costs may arise. Despite this, manual pumps remain a cost-effective solution for scenarios that don’t require continuous or automated functionality.

Limitations of Manual Pumps

While manual submersible pumps offer flexibility and cost advantages, they also come with certain limitations that can impact their efficiency and durability. Understanding these challenges is essential to ensure their proper use and maintenance.

Need for Constant Monitoring

One of the key limitations of manual submersible pumps is the need for constant monitoring during operation. In applications where human intervention is required to manage the pump, this can be inconvenient, particularly for frequent or prolonged pumping, as it demands constant attention to ensure effective operation.

Potential for Wear and Tear

Another drawback of manual pumps is the increased risk of wear and tear due to dry running. Without automated mechanisms to regulate operation, these pumps can be damaged if they continue running after the fluid level has dropped too low.

This not only shortens the pump’s lifespan but can also lead to higher maintenance and replacement costs over time, making proper monitoring essential to avoid unnecessary damage.

What is an Automatic Pump?

An automatic submersible pump is a highly efficient and user-friendly solution designed to operate independently. Equipped with advanced mechanisms such as float switches or electrode systems, these pumps automatically start and stop based on water levels.

This self-regulating functionality ensures consistent performance without requiring manual intervention, making them ideal for applications where maintaining specific water depths is crucial.

By responding to changing conditions automatically, these pumps not only save time but also enhance operational efficiency and reliability.

Types of Automation Mechanisms

Automatic submersible pumps utilise different types of mechanisms to regulate their operation, ensuring efficient performance and protection against damage. Two of the most common systems are float switches and electrode systems, each offering unique benefits for specific applications.

Float Switch Systems

Float switch systems rely on a waterproof pump casing that houses a micro-switch, which is activated by the movement of the float in response to water levels. As the water rises, the float triggers the switch to start the pump; when the water level drops, the switch stops the operation.

These systems can be directly connected to the pump. Float switches are simple yet effective, making them a popular choice for a wide range of applications.

Electrode Systems

Electrode systems provide a more advanced level of automation, using relays embedded within the pump to monitor water levels. These systems prevent dry running by ensuring the pump stops when water levels fall below a certain point.

Additionally, they include timer functionality, which optimises operation by reducing unnecessary power usage. Electrode systems are ideal for applications requiring precision and efficiency, extending the pump’s lifespan and reducing energy consumption.

Advantages of Automatic Submersible Pumps

Automatic submersible pumps offer several advantages that make them a reliable and efficient choice for various applications. From energy savings to reduced maintenance demands, these features provide long-term benefits for users.

Energy Efficiency

One of the key advantages of automatic pumps is their ability to significantly reduce power consumption. According to Tsurumi comparisons, these pumps can lower energy usage by up to 40% compared to non-automatic models.

By operating only when water levels require it, electric submersible pumps not only save electricity but also contribute to more sustainable operations.

Extended Pump Lifespan

Automatic pumps are designed to protect against dry running, a common cause of wear and damage in manual models.

By stopping operation when water levels fall too low, these pumps reduce unnecessary strain on components, extending their lifespan and lowering maintenance costs. This ensures reliable performance over time, even in demanding conditions.

Minimal Monitoring Requirements

Another significant advantage of automatic pumps is their ability to operate independently. Unlike manual models, these pumps do not require human intervention to start or stop, freeing up valuable time and resources.

This feature makes them ideal for applications where consistent water management is needed without constant oversight.

Limitations of Automatic Pumps

While automatic submersible pumps offer numerous benefits, they do come with certain limitations. One of the primary drawbacks is their higher upfront cost compared to manual models, which can make them less accessible for budget-sensitive projects.

Additionally, installing an automatic pump can sometimes require more effort and expertise, particularly for complex setups involving starter panels or custom configurations.

Despite these initial challenges, the long-term savings in energy and maintenance often make automatic pumps a worthwhile investment.

Comparison: Manual vs Automatic Submersible Pumps

Key Differences

When deciding between manual and automatic submersible pumps, understanding their key differences can help ensure you choose the right option for your needs. Here’s how these two types compare:

- Operation: Manual pumps rely on human intervention manually or via control panels for starting and stopping, while automatic pumps are equipped with self-regulating mechanisms that manage operations based on water levels.

- Energy Efficiency: Automatic models are designed to conserve energy by activating only when necessary, offering substantial savings compared to manual pumps that may run unnecessarily if not closely monitored.

- Applications: Automatic pumps are better suited for consistent water level management and continuous operation in demanding environments.

Cost Considerations

Cost is a crucial factor when selecting between manual and automatic submersible pumps. Understanding the financial implications of each option can help you make a choice that aligns with your budget and long-term needs.

Manual Pumps

Manual submersible pumps are generally more affordable upfront, making them a cost-effective solution for projects with limited budgets or temporary applications.

However, if you need to enhance their functionality by integrating them with a control panel, additional installation costs may be required. Despite this, their simplicity and lower starting price make manual pumps an appealing option for straightforward or short-term use.

Automatic Pumps

Automatic pumps come with a higher initial cost due to their advanced mechanisms, but this expense is often offset by the long-term operational savings they provide.

With features that reduce energy consumption and extend the pump’s lifespan, automatic models can lower ongoing costs significantly.

While the upfront investment may be greater, their efficiency and reduced maintenance needs make them a valuable option for applications requiring consistent and reliable operation.

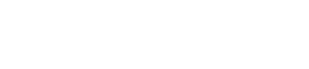

Tsurumi Pump Range with Manual and Auto Options

Overview of Available Models

Tsurumi offers a versatile range of submersible pumps designed to meet the needs of various industries, with both manual and automatic options available. Each series is tailored to deliver reliable performance, ensuring users can find the right pump for their specific requirements.

B Series

The B Series pumps are robust and efficient, suitable for handling general-purpose dewatering tasks. Their durable construction ensures dependable operation across a wide range of applications.

LB Series

The LB Series includes models equipped with advanced electrode mechanisms for automatic operation. These pumps provide excellent energy efficiency and are ideal for applications where maintaining specific water levels is essential.

PU Series

The PU Series stands out for its Auto-Alternation models, which include three floats for enhanced automation. This design allows multiple pumps to operate seamlessly without the need for a control panel, making them a practical choice for more complex setups.

PN, TM, HS, UT, KTV, KTZ Series

Tsurumi’s extensive range also includes the PN, TM, HS, UT, KTV, and KTZ Series, each designed for specific industrial and environmental conditions.

From corrosion-resistant models to heavy-duty dewatering solutions, these pumps offer flexibility and reliability across a variety of challenging applications.

Highlighted Features

The Auto-Alternation models in the PN and PU Series are designed to simplify complex pumping systems. These models include three floats, allowing multiple pumps to operate in coordination without the need for a separate control panel.

This innovative design ensures efficient performance and reduces installation costs, making it an ideal choice for large-scale or high-demand applications.

For a detailed visual explanation of how Auto-Alternation works, watch the video here: Tsurumi Auto-Alternation System.

Choosing the Right Pump for Your Needs

Factors to Consider

Selecting the right submersible pump is essential for ensuring optimal performance and cost-effectiveness in your application. Here are some key factors to consider when making your decision:

- Fluid Levels and Frequency of Use: Assess whether the water levels in your application are inconsistent or require continuous management to determine whether a manual or automatic pump is the better option.

- Energy Efficiency Goals: Factor in the importance of reducing power supply consumption to lower operational costs and support sustainable practices over time.

- Budget and Installation Requirements: Weigh the initial purchase cost against potential long-term savings, including any additional expenses for installation or upgrades to meet your operational demands.

When to Choose Manual vs Automatic

When to Choose Manual vs Automatic

Choosing between a manual or automatic submersible pump depends on your application’s needs. Manual pumps are ideal for simple operations with irregular or occasional use, offering a cost-effective solution for those who don’t need continuous operation.They work well where water levels are inconsistent and manual control is sufficient. Automatic pumps, however, provide long-term efficiency and reliability.

By managing water levels automatically, they reduce maintenance and wear, making them ideal for applications requiring consistent performance with minimal intervention.

Discover Reliable Submersible Pump Solutions with Tsurumi

At Tsurumi, we offer a wide range of high-quality sump pumps designed to meet the unique needs of various industries. Whether you’re looking for a cost-effective manual pump or an efficient automatic model, our pumps deliver reliable performance, durability, and energy savings.

Trust Tsurumi to provide the ideal solution for your application, ensuring optimal pump operation and long-term value. Contact us today to learn more about our products and find the perfect pump for your needs.

When to Choose Manual vs Automatic

When to Choose Manual vs Automatic