In the pump industry, selecting the right materials is critical for ensuring long-term durability and efficiency in wastewater and sewage applications.

Pumps operate in harsh conditions, facing corrosive liquids, abrasive solids, and varying pH levels. Material choice directly impacts lifespan, reliability, and maintenance needs.

Corrosion resistance, wear resistance, and chemical compatibility determine suitability for specific applications. The wrong material can cause premature wear, breakdowns, and higher costs.

This guide explores the importance of pump material selection, its impact on performance, and the best options for wastewater and sewage systems.

Why Pump Material Matters

Why Pump Material Matters

Impact on Performance and Longevity

Pump material selection is crucial for efficiency, lifespan, and reliability. The right material resists corrosion, abrasion, and chemical exposure, reducing wear and extending service life.

In contrast, unsuitable materials deteriorate quickly, leading to frequent maintenance and costly downtime. Exposure to acidic or abrasive fluids accelerates wear if materials are not properly matched, reducing efficiency and increasing expenses.

Choosing durable, application-specific materials optimises performance, minimises failures, and lowers long-term costs.

Environmental and Application Considerations

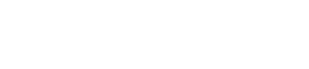

Pump materials must be selected based on the specific operating environment to ensure durability and efficiency. Sewage, wastewater, seawater, and chemical applications expose pumps to varying levels of corrosion and abrasion, requiring materials suited to these conditions.

pH levels, ranging from 0 to 14, play a key role in suitable material selection, as highly acidic or alkaline fluids can accelerate deterioration. Additionally, abrasive solids cause excessive wear on components, while corrosive liquids weaken structural integrity over time.

Choosing the appropriate material ensures resistance to these factors, improving performance and extending the pump’s operational life.

Common Pump Materials and Their Applications

Selecting the right pump material is essential for ensuring efficiency, durability, and long-term performance. Different environments, such as from wastewater treatment to seawater applications, require materials that can withstand specific conditions such as corrosion, abrasion, and chemical exposure.

Below are the most commonly used pump materials and their ideal applications.

Resin-Based Pumps

Resin-based pumps provide a lightweight yet durable solution for handling corrosive and chemically aggressive fluids. Designed for enhanced longevity, these pumps utilise advanced resin compositions to deliver superior resistance compared to standard resin pumps.

They are an excellent choice for environments where exposure to acidic substances and wastewater is common.

Advantages:

- Corrosion resistant and lightweight, making handling and installation easier

- Highly durable against acidic and chemical exposure, ensuring long-term reliability

Best for Applications Like:

- Sewage, wastewater, and rainwater drainage, where corrosion resistance is essential

- Septic tanks, small wastewater treatment facilities, and kitchen wastewater traps in homes and businesses

- Water circulation in koi ponds and fish farms, ensuring safe and efficient water flow

Tsurumi Models: PN, PU (resin & stainless steel), TM series (resin & titanium)

Titanium Pumps

Titanium pumps are specifically designed for extreme environments where corrosion resistance is critical. Their ability to withstand highly acidic and saline conditions makes them ideal for marine applications and industries requiring long-term durability in chemically harsh settings.

Advantages:

- Outstanding corrosion resistance, particularly in seawater and acidic environments

- Exceptional strength and longevity, even under prolonged exposure to extreme conditions

- Handles extreme pH levels (1-13), making them suitable for a wide range of applications

Best for Applications Like:

- Pumping seawater in marine vessels, aquariums, and saltwater aquaculture, where exposure to high chloride levels is common

- Circulating seawater in breeding ponds to maintain optimal water conditions for aquatic life

Tsurumi Model: TM series

Cast Iron Pumps

Cast Iron Pumps

Cast iron is one of the most commonly used pump materials due to its robust construction and affordability. While it does not offer the same corrosion resistance as stainless steel or titanium, it is highly durable in applications where exposure to extreme chemicals is minimal.

Cast iron pumps are often chosen for their balance of cost-effectiveness and performance in non-corrosive wastewater systems.

Advantages:

- A widely used, budget-friendly material offering strong structural integrity

- Suitable for non-corrosive wastewater applications, where chemical exposure is limited

- Handles pH values between 5-13, making it versatile for many wastewater and drainage systems

Best for Applications Like:

- General wastewater and sewage systems in residential, commercial, and industrial settings

- Tough conditions requiring increased wear resistance, such as high-flow drainage applications

Tsurumi Model: CZ series (upgraded FC250 grey cast iron for enhanced durability and wear resistance)

Stainless Steel Pumps (316 & 304)

Stainless steel pumps are engineered for extreme conditions, offering superior resistance to both abrasion and corrosion. These pumps perform exceptionally well in industries that handle chemically aggressive or acidic liquids, where durability and longevity are essential.

They are widely used in construction, mining, and chemical processing facilities where standard materials degrade quickly.

Advantages:

- High durability in demanding environments such as construction, mining, and chemical plants

- Resistant to aggressive and corrosive acidic liquids, ensuring reliability in chemically harsh settings

- Withstands wastewater containing abrasive substances, reducing wear and maintenance requirements

- 316 stainless steel handles pH values between 2.5-13, while 304 stainless steel is suited for pH levels between 3.5-13

Best for Applications Like:

- Mines, quarries, and wastewater treatment facilities, where exposure to heavy sediment and corrosive materials is frequent

- Chemical processing industries that require pumps capable of handling harsh chemicals and acidic solutions

Tsurumi Stainless Steel Series: Designed for extreme durability in harsh environments, ensuring long-lasting performance in the most challenging applications

Choosing the right pump material is crucial for maintaining efficiency, reducing long-term costs, and ensuring reliability in demanding conditions.

Proper material selection minimises wear, prevents premature failure, and extends the operational life of the pump, ultimately leading to improved performance and reduced downtime.

The Role of Wear Parts in Pump Performance

Impeller Materials and Their Suitability

Impeller Materials and Their Suitability

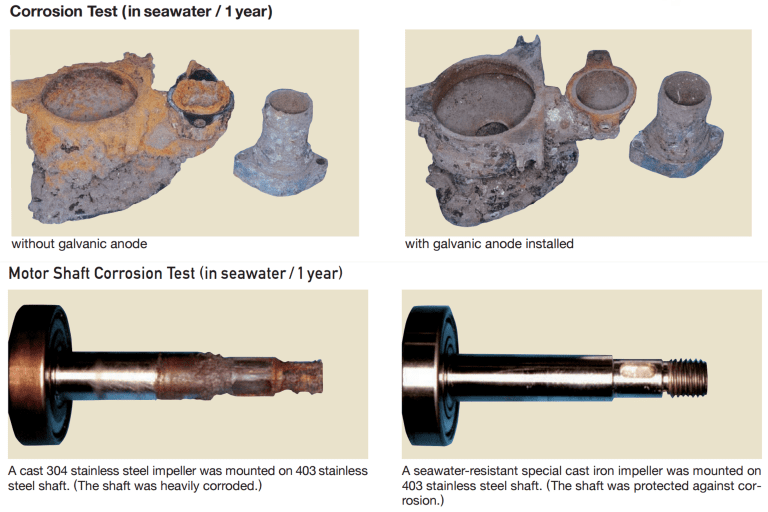

Wear parts, such as impellers, play a critical role in a pump’s efficiency, durability, and overall performance. Selecting the right impeller material ensures resistance to wear, corrosion, and impact, reducing maintenance costs and extending operational life.

Different materials offer varying levels of strength and resistance, making it essential to match them to specific application requirements.

- Urethane Rubber: A lightweight and impact-resistant material ideal for applications requiring flexibility and abrasion resistance, particularly in handling solids-laden fluids.

- Cast Iron: A cost-effective and durable option for non-abrasive environments, providing a balance of affordability and strength in standard wastewater applications.

- High-Chromium Cast Iron: Designed for high wear resistance, this material is well-suited for abrasive applications where extended durability is required.

- Stainless Steel: Offers excellent corrosion and chemical resistance, making it ideal for acidic or chemically aggressive environments.

- Tungsten Carbide Alloy: Provides superior durability in extreme wear conditions, offering exceptional hardness and longevity in high-stress applications.

- Glass-Fibre Reinforced: Enhances strength and longevity by improving impact resistance and structural integrity, particularly in demanding environments.

Choosing the appropriate impeller material ensures optimal pump efficiency, minimises wear, and extends service life, making it a key factor in long-term operational reliability.

Choosing the Right Pump Material: Key Considerations

Understanding factors affecting material selection is crucial for choosing the most durable and cost-effective option. Key considerations include liquid composition, operating conditions, and the balance between cost and performance.

1. Understanding the Liquid Composition

The chemical properties of the pumped liquid play a critical role in material selection. pH levels, ranging from highly acidic to highly alkaline, can significantly impact a pump’s longevity, making corrosion-resistant materials essential for extreme conditions.

Additionally, the presence of solids and abrasive particles influences wear part selection, as harder materials, such as high-chromium cast iron or tungsten carbide, are necessary to withstand excessive wear.

2. Operating Conditions and Lifespan

Pump materials must be suited to the specific environmental conditions in which they operate. Factors such as exposure to seawater, chemical processing, or heavy sediment influence material durability.

Selecting a material that aligns with these conditions reduces maintenance needs, minimises unplanned downtime, and extends the pump’s service life. Matching material properties to the application helps optimise reliability and long-term performance.

3. Cost vs. Performance Trade-Offs

While budget constraints are an important factor in pump selection, balancing initial investment with long-term efficiency is crucial.

Lower-cost materials may be suitable for less demanding environments, but premium materials, such as titanium or stainless steel, provide enhanced durability and resistance in harsh conditions.

In applications where frequent maintenance and part replacement would lead to high operational costs, investing in high-quality materials ensures long-term savings and uninterrupted performance.

Choose Durable, High-Performance Pumps with Tsurumi

Selecting the right pump material is essential for ensuring efficiency, longevity, and reliability in sewage and wastewater applications. Matching materials to specific environmental conditions helps minimise wear, reduce maintenance costs, and optimise pump performance.

Tsurumi Pumps offers a range of durable, corrosion-resistant solutions designed to withstand demanding conditions, from wastewater treatment to industrial applications. Built for reliability and long-term efficiency, our efficient pumps deliver proven performance in the toughest environments.

Trust Tsurumi to provide high-quality pumping solutions tailored to your needs. Explore our range today or contact us to find the right pump for your application.

Why Pump Material Matters

Why Pump Material Matters Cast Iron Pumps

Cast Iron Pumps Impeller Materials and Their Suitability

Impeller Materials and Their Suitability