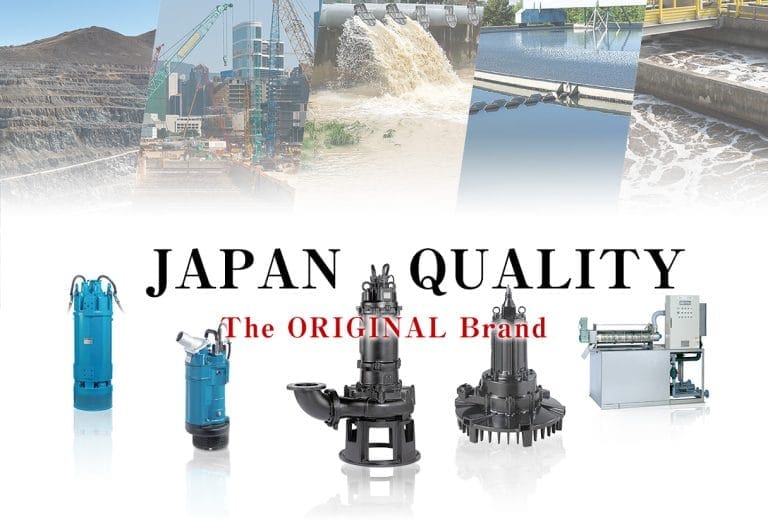

Submersible pumps are essential tools in industries that rely on efficient fluid management. Designed to operate while fully submerged, these pumps are commonly used across Australia in sectors such as construction, mining, industrial, sewage and wastewater treatment.

With a wide range of models and applications available, selecting the right submersible pump is critical to ensuring reliable performance, reducing maintenance needs, and extending equipment lifespan.

As industry demands evolve, there is increasing focus on pump quality—not just for initial performance but for long-term value and operational efficiency. Choosing a well-built, reliable pump can significantly impact both productivity and cost over time.

Understanding Pump Quality: High vs Low

What Makes a Pump “High Quality”?

What Makes a Pump “High Quality”?

Understanding what defines a high-quality submersible pump is essential for informed decision-making. These pumps are built with durable materials like high-chromium cast iron and stainless steel, offering strong resistance to wear and corrosion.

Key components, such as dual mechanical seals with silicon carbide, enhance durability and outperform standard materials under tough conditions. Quality pumps are also designed for ease of use, allowing for straightforward installation, operation, and maintenance.

Together, these features ensure reliable long-term performance, making them a smart choice for demanding environments.

Common Signs of Low-Quality Pumps

- Inferior Materials: Constructed from low-grade materials such as plastic or thin metal, increasing the risk of early wear and corrosion.

- Short Lifespan: Prone to frequent breakdowns, resulting in reduced operational life and higher maintenance demands.

- Lack of Certification: Often missing recognised quality certifications, making performance and safety standards uncertain.

- Limited Support: Minimal warranty coverage and poor customer service reduce long-term value and reliability.

Why Tsurumi Pumps Are a Benchmark for High Quality

Over 100 Years of Expertise in Pump Technology

Over 100 Years of Expertise in Pump Technology

With over a century of experience in pump technology, Tsurumi Pump is a recognised global leader in the submersible pump industry. Its reputation is built on consistent performance, reliability, and innovation across diverse applications.

Continued investment in research, development, and thorough product testing ensures each pump meets high standards for durability and efficiency. This strong focus on quality, backed by a worldwide presence, makes Tsurumi a trusted benchmark for those seeking dependable, long-term pump solutions.

Exclusive Features Designed for Longevity

Tsurumi pumps are engineered with advanced features that prioritise long-term reliability and performance, even in the most demanding environments. These design elements go beyond industry standards to deliver superior durability, operational efficiency, and ease of maintenance.

Oil Lifter Innovation

A key innovation unique to Tsurumi, the oil lifter is designed to protect the mechanical seals—one of the most critical components in a submersible pump.

By ensuring proper lubrication at all times, this feature significantly reduces wear, outperforming similar attempts by other manufacturers. As a result, the internal parts enjoy an extended service life, reducing the frequency of maintenance and unexpected breakdowns.

Robust Build and Materials

Tsurumi pumps are built using thick, heavy-duty casings that offer strong resistance to corrosion and physical stress. This robust construction ensures reliable operation in harsh and abrasive environments.

Internally, the use of silicon carbide seal faces—five times stronger than traditional tungsten carbide—enhances wear and heat resistance, further extending the pump’s operating life.

Precision and Quality Manufacturing

Tsurumi maintains strict control over its manufacturing process to ensure every component meets exacting standards. Using in-house casting methods, including 3D printing technology, the company achieves faster turnaround times and greater precision in part fabrication.

All processes are certified under ISO 9001 and ISO 14001, reflecting a strong commitment to quality and environmental responsibility. Advanced production tools, such as NC machines and high-accuracy measuring instruments, support the consistent delivery of high-performance pump components

Designed with the User in Mind

Tsurumi pumps are thoughtfully designed to meet the practical needs of users in the field. With straightforward installation and easy-to-maintain components, they reduce downtime and simplify routine servicing.

This user-friendly approach is especially valuable in remote or high-demand environments. Built to perform reliably in tough Australian conditions—from dry, dusty sites to wet, corrosive settings—Tsurumi pumps offer consistent, hassle-free operation where it matters most.

Risks of Choosing Low-Quality Pumps

While low-cost pumps may appear appealing at first, they often lead to ongoing issues that compromise performance, increase operating costs, and shorten equipment lifespan. Understanding the risks can help avoid costly mistakes over time.

- The Hidden Costs Behind Cheap Prices: A lower upfront price can quickly be outweighed by higher lifetime costs due to poor reliability and inefficient performance.

- Frequent Downtime and Replacements: Substandard pumps often fail prematurely, leading to unexpected breakdowns and the need for frequent replacements.

- Higher Energy Consumption: Inexpensive models may lack the engineering precision of quality pumps, resulting in less efficient operation and increased power usage.

- Poor Construction = Reduced Performance: Thin casings and inferior materials are more prone to corrosion and leaks, especially in harsh or abrasive environments.

- Low Durability Under Pressure: In demanding conditions, lower-grade pumps wear out quickly, reducing their ability to perform consistently over time.

- Lack of Genuine Parts and Support: Many low-cost brands don’t offer access to precision-made spare parts, making repairs difficult and less reliable.

- Limited Service Options: Without dedicated support or compatible components, maintaining or servicing these pumps becomes time-consuming and costly.

Real-World Considerations for Australian Buyers

When selecting a submersible pump, Australian buyers face a wide range of conditions—from arid, remote regions to high-moisture, corrosive environments. Choosing a pump that aligns with local site demands and industry requirements is critical to ensuring long-term performance and reliability.

Beyond technical specifications, it’s important to consider after-sales support, spare parts availability, and how well the pump will handle Australia’s tough operating conditions.

Common Mistakes Made by First-Time Buyers

Common Mistakes Made by First-Time Buyers

- Focusing Only on Price: Many first-time buyers are tempted to choose the cheapest option available, but this often leads to higher maintenance costs, reduced efficiency, and a shorter equipment lifespan.

- Overlooking Environmental Conditions and Application Type: Selecting a pump without considering factors like water type, site abrasiveness, or operational frequency can result in poor performance or early failure. Each application demands a specific pump design tailored to those conditions.

What to Ask When Buying a Pump

Asking the right questions before purchasing a pump can help avoid costly issues down the track. A quality pump is more than just its performance on day one—it’s about how well it holds up over time and how easily it can be supported.

- Does the Pump Meet ISO Standards?: Look for compliance with international quality and environmental standards such as ISO9001 and ISO14001. These certifications reflect a manufacturer’s commitment to consistent quality and responsible production.

- What Materials Are Used in Construction?: Understanding the materials used—such as high-chromium cast iron, or silicon carbide mechanical seals—can indicate how well the pump will resist corrosion, abrasion, and wear over time.

- Is There Local Support and Access to Genuine Parts?: Choose a supplier that offers ongoing support, service options, and readily available genuine parts. This ensures your pump stays in top condition and is easy to maintain when needed.

Final Thoughts: Investing in Reliability with Tsurumi

Choosing a high-quality submersible pump isn’t just about solving today’s challenges—it’s about securing long-term performance, safety, and value.

Tsurumi’s proven commitment to quality, innovation, and durability makes it a trusted choice across Australia’s toughest conditions. Instead of focusing solely on upfront costs, consider the full lifecycle value of your investment.

Ready to invest in reliability? Talk to your local Tsurumi distributor today, or contact us directly to find the right solution built to last.

What Makes a Pump “High Quality”?

What Makes a Pump “High Quality”? Over 100 Years of Expertise in Pump Technology

Over 100 Years of Expertise in Pump Technology Common Mistakes Made by First-Time Buyers

Common Mistakes Made by First-Time Buyers