Reliable Pumping Solutions for Australian Sites

At Tsurumi Australia, we understand that dependable pumps are the backbone of many everyday operations, from construction and mining to dewatering and home drainage.

At Tsurumi Australia, we understand that dependable pumps are the backbone of many everyday operations, from construction and mining to dewatering and home drainage.

Single-phase pumps, in particular, are essential where three-phase power isn’t available. They’re compact, efficient, and easy to operate, making them ideal for smaller or mobile sites.

Tsurumi’s single-phase submersible pumps are trusted across Australia for their reliability and long service life. With proper care and maintenance, they can deliver years of trouble-free operation even in demanding environments.

In this guide, we’ll explore the most common issues with single-phase pumps, the mistakes that often cause failures, and the maintenance practices that help maximise their lifespan and performance.

What Are Single-Phase Pumps?

Single-phase pumps are electric-driven units that use a standard single-phase power supply, making them perfect for smaller sites or temporary installations where three-phase power isn’t available.

They combine a single-phase motor and impeller in a single compact housing, designed for efficiency and convenience. Whether you’re dewatering a construction pit, draining a flooded basement, or managing groundwater, these pumps offer the right balance between performance and portability.

Why Tsurumi Pumps Are Trusted in Australia

Tsurumi has earned a worldwide reputation for building pumps that stand up to tough conditions.

Across Australia, operators rely on our products for their:

- Proven engineering and build quality

- Reliable operation in harsh environments

- Ease of maintenance and long lifespan

- Comprehensive range, from drainage to construction-grade dewatering pumps

Whether it’s a small home project or a large-scale worksite, there’s a Tsurumi pump built to suit your needs.

Common Problems with Single-Phase Pumps (and How to Fix Them)

Even the best pumps can experience occasional performance issues. Recognising and addressing these early can prevent downtime and costly repairs.

Pump Won’t Start

If your pump doesn’t start, it’s usually something simple:

- Check that the power supply, cords, and circuit breakers are functioning properly

- If your pump uses a float switch, listen for a clicking sound when lifting it; this confirms it’s operating correctly

- For electrode sensor pumps, clean the sensor to remove any buildup that could prevent activation

Low Flow or No Water Movement

When the pump runs but isn’t moving water effectively:

- Inspect for a blocked suction area or clogged impeller

- Make sure the pump is correctly sized for the application, whether it’s for industrial applications or household applications

- If sitting on soft or muddy ground, lift the pump slightly; sediment underneath may be restricting flow

- Inspect pipe work and hoses for blockages or kinks

Overheating or Automatic Shutdown

Overheating is one of the most common issues, often caused by running the pump dry or insufficient cooling.

- Always ensure the pump has enough water coverage – refer to manual or data sheets

- If the unit stops automatically, allow time for it to cool down before restarting

- Check the ventilation when operating the pump in a confined space

Unusual Noise or Excessive Vibration

Loud or uneven sounds often signal mechanical issues.

- Look for loose bolts, fittings, or worn bearings

- Clean any blockages in the suction area

- Cavitation, when the pump runs with restricted water flow, can also cause vibration and shorten the lifespan

By addressing these issues promptly, you can restore full performance and protect the internal components of your pump.

Common Mistakes That Shorten Pump Life

Many pump failures stem from avoidable user errors. Knowing what to avoid is just as important as knowing how to fix problems.

Running the Pump Dry

Running a pump without sufficient water quickly damages the mechanical seal and can lead to overheating. Always make sure there’s enough liquid to cover the suction inlet before switching the pump on. If unclear how much your pump should be submerged, refer to the operation manual or data sheets.

Overloading the Pump

Every pump is designed for a specific flow rate and head. Operating beyond these limits puts extra strain on the motor and impeller, shortening its lifespan.

Using the Wrong Pump for the Job

Not all pumps are built for the same purpose. Using a clean water pump for muddy or slurry applications can cause blockages and severe wear. Always choose a model designed for your liquid type, pH level, temperature, and solids content.

Ignoring Early Warning Signs

Small changes, like reduced output, noise, or vibration, often indicate developing issues. Regular inspection helps prevent major breakdowns later on.

Pro Tip: Always match the pump to the environment and task.

If you’re unsure which model best suits your needs, contact Tsurumi Australia’s expert team. We’ll help you choose the right pump for the job and operating conditions.

Maintenance Tips to Maximise Pump Life and Efficiency

Maintenance Tips to Maximise Pump Life and Efficiency

A well-maintained pump performs more efficiently, saves energy, and lasts longer. Routine care is key to getting the most from your investment.

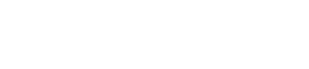

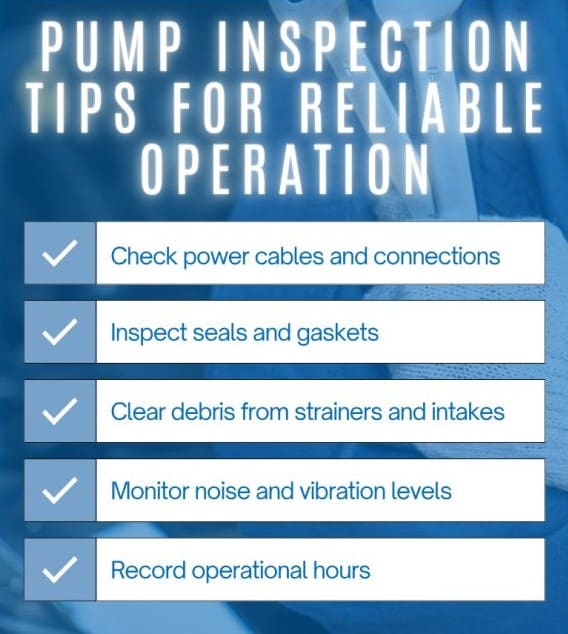

Routine Inspections

- Check power cables, hoses, and fittings for cracks or wear

- Inspect and clean the impeller and strainer to remove buildup or blockages

Preventing Overheating

- Avoid running dry or exceeding duty cycles

- Maintain the correct water level to keep the motor cool

- Ensure proper ventilation, if the pump operates in an enclosed space

Smart Cable Management

- Never lift or carry the pump by its cable as it will damage it

- Avoid tight bends or exposure to sharp surfaces

- Replace damaged cables immediately to prevent electrical faults

Scheduled Servicing

- Follow Tsurumi’s recommended maintenance intervals

- Always use genuine spare parts to maintain and reliability

- Keep a simple maintenance record; it helps track performance and service needs.

Consistent maintenance not only extends your pump’s life but also keeps it running safely and efficiently.

Why Choose Tsurumi Single-Phase Pumps in Australia

Built for Harsh Australian Conditions

Tsurumi pumps are engineered to handle Australia’s demanding environments, from sandy mine water to heavy clay-laden runoff. With rugged materials and precision assembly, they provide consistent performance and long-term durability.

Innovative Design and Technology

Innovative Design and Technology

Our single-phase range includes both electrode sensor and float switch models, giving users options for automatic or manual operation.

- Electrode sensor pumps – LB-A

- Automatic start/stop when water levels change

- Ideal for unattended operation in sumps or pits

- Float switch pumps – HSZ, PNA, PNW, PUA, PUW, TMA, UTZ

- Proven reliability for drainage and dewatering

- Simple, durable design for easy maintenance

Proven Reliability and Value

Every Tsurumi pump is designed for longevity, backed by a strong national distributor network. With genuine parts and technical support across Australia, you can depend on fast service when you need it most.

Choosing the Right Pump for Your Project

Selecting the correct pump ensures reliable operation and protects your equipment investment.

Match the Pump to Your Application

- Construction Dewatering: Manage groundwater and rainwater on-site

- Drainage: Clear flooded basements or pits efficiently

- Light Slurry or Wastewater Handling: Suitable for industrial facilities or mining sites

Key Factors to Consider

- Power Supply: Single-phase voltage availability

- Flow Rate and Head: Determine discharge distance and height

- Liquid Characteristics: Consider solids content, pH, and temperature

Expert Support from Tsurumi Australia

Choosing the right pump doesn’t have to be complicated. Our local team provides expert recommendations, ensuring your pump matches your site requirements and delivers peak efficiency.

Final Thoughts

A single-phase pump is a dependable workhorse, but only if it’s installed, operated, and maintained correctly. By avoiding simple mistakes like running dry, overloading, or neglecting routine checks, you can extend your pump’s life and maintain reliable performance for years.

At Tsurumi Australia, we’re proud to supply pumps designed for the harshest conditions, backed by local support and decades of proven engineering.

Looking for reliable submersible or dewatering pumps in Australia? Explore our full range of single-phase pumps online, purchase online, or speak with our team today for expert advice.

Maintenance Tips to Maximise Pump Life and Efficiency

Maintenance Tips to Maximise Pump Life and Efficiency Innovative Design and Technology

Innovative Design and Technology