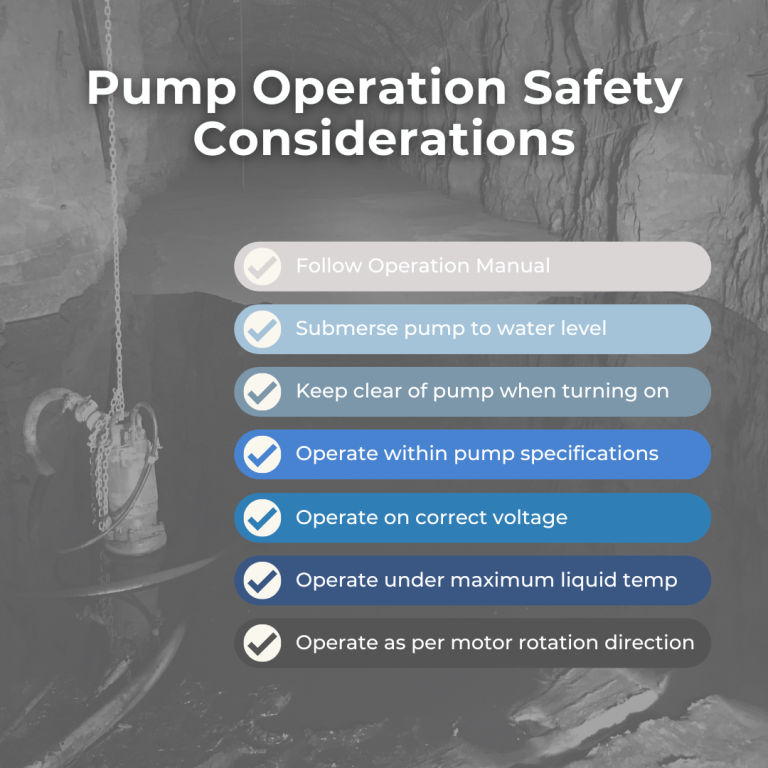

Operating submersible pumps requires more than technical know-how; it demands strict adherence to safety procedures to ensure both efficiency and safety.

These essential pumps manage water in various settings—from construction sites to residential basements. However, improper handling can pose serious risks.

This article explores crucial safety concerns for using submersible pumps, guiding to prevent accidents and prolonging equipment life. By understanding and implementing these measures, operators can protect themselves and their surroundings from potential dangers.

Importance of Safety in Operating Submersible Pumps

The importance of safety when operating submersible pumps is critical. Unsafe practices can lead to severe consequences, including personal injury, equipment damage, and significant operational failures with potential financial and legal repercussions.

Adhering to safety guidelines mitigates these risks, enhances equipment efficiency, and ensures compliance with health and safety regulations.

Proper safety measures extend the lifespan of submersible pumps, improve performance, and create a safer working environment, thereby reducing the likelihood of accidents and associated costs.

Overview of Submersible Pumps

Submersible pumps are designed to operate fully immersed in liquid, enhancing their efficiency and reliability. Their compact, waterproof construction enables them to push fluid to another location, which makes them highly effective.

Widely used in Australia, these pumps are essential for draining floods, managing sewage and wastewater, and dewatering. They also serve in industrial contexts, such as mining and construction, demonstrating their versatility across various environments.

Pre-Operational Safety Checks

Inspecting the Pump Before Use

Pre-operational safety checks are essential for submersible pumps’ safe and effective use. Before use, inspecting the pump for any signs of damage or wear that could affect its function is crucial.

Additionally, verify that the pump is compatible with the substance it will handle, considering the chemical properties and viscosity of the fluid. These steps ensure the pump’s performance and prevent potential electrical hazards and maintaining operational integrity.

Electrical Safety and Setup

Electrical safety is crucial for the efficient and safe operation of submersible pumps. It’s essential to ensure that the pump’s voltage aligns with the specifications on the nameplate, maintaining a variation limit within ±10%. This prevents electrical overload and minimises equipment failure.

Operators must avoid powering other equipment with the same generator used for the submersible pump.

This ensures a stable power supply and reduces the risk of voltage fluctuations, which can cause malfunctions or breakdowns. Adhering to these guidelines helps maintain safety standards and extends the pump’s operational life.

Safe Operation Practices

Starting and Operating the Pump

Safe operation practices are crucial when starting and operating submersible pumps to prevent accidents and ensure efficiency. It’s essential to maintain a safe distance from the pump during startup, as it may kick out, posing a risk of injury.

Additionally, ensure the pump is always submerged in liquid during operation. Submersible pumps rely on this immersion for cooling and proper function; running them dry can cause overheating and damage. Following these practices enhances safety and prolongs the pump’s lifespan.

Handling and Adjusting the Pump

Handling and adjusting submersible pumps must be done with safety precautions. Always turn off the pump before relocating or making any adjustments to avoid unintended operation and potential injuries.

Additionally, never perform maintenance or adjustments when someone is in a sump, as this exposes them to significant risks.

Compatibility and Chemical Handling

- Ensuring Substance Compatibility: Verify that the substances being pumped are suitable for the specific type of submersible pump being used. Avoid using the pump for acids, corrosive, flammable substances, or fluids more viscous than the pump is designed to handle.

- Risk of Using Incompatible Substances: Using the pump with incompatible materials can lead to equipment failure, hazardous conditions, and potential safety risks. Always refer to the manufacturer’s specifications/instructions for compatible substances.

- Precautionary Measures: If there is any doubt about the compatibility of a substance, refrain from operating the pump. Consult with technical support to clarify suitable use.

Motor Rotation Check

Before commencing operation, ensure that the electric motor is rotating in the correct direction as indicated on the data plate. Incorrect motor rotation can lead to inefficient pump performance and potential mechanical damage.

Managing Operational Issues

Monitoring for Anomalies

Managing operational issues effectively requires monitoring for any signs of malfunction in submersible pumps. Operators should be on the lookout for unusual noises, vibrations, or odours, which often indicate underlying mechanical wear or obstructions.

Recognising these anomalies early is crucial, as they can lead to more serious damage if unaddressed. Should any such signs be detected, it is essential to immediately shut down the pump and consult with a Tsurumi representative.

Continuing to operate the pump under these abnormal conditions may result in an electric shock, fire, water leakage, or further damage to the pump.

Temperature and Environmental Considerations

When operating submersible pumps, adhering to temperature and environmental considerations is critical for both safety and equipment integrity. It’s essential to ensure that the liquid’s temperature does not exceed the pump’s maximum recommended levels to prevent damage to the pump.

Additionally, handle the pump with care after operation, especially since it can become very hot. Touching the pump with bare hands during or immediately after the operation can lead to burns, so always allow the pump to cool down before handling.

These precautions help prevent potential hazards such as electrical leakage or burns, thereby maintaining both operator safety and pump functionality.

Post-Operational Procedures

Shutting Down and Storage

Proper post-operational procedures are essential to maintain the longevity and safety of submersible pumps. When shutting down the pump, follow the manufacturer’s guidelines to ensure it is done safely and correctly.

After shutdown, store the pump in a dry, clean environment to prevent corrosion and damage. Proper storage not only preserves the pump’s condition but also ensures it is ready for safe use in the future.

Maintenance and Repair

Proper maintenance and professional repairs are vital for the longevity and safe operation of submersible pumps. Consistently servicing the water pump according to the manufacturer’s guidelines helps prevent unforeseen pump failures and extends its operational life.

Additionally, for any repairs beyond routine maintenance, it’s crucial to consult with Tsurumi’s representatives. This ensures that repairs are conducted properly, maintaining the pump’s performance and safety standards.

Checking for Backflow

After stopping the pump, ensure that any backflow has ceased before turning it on again, particularly if there is a non-return valve in the line or in the pump. This step helps prevent damage and maintains the integrity of the pumping system.

Conclusion

In conclusion, adhering to safety guidelines when operating submersible pumps is essential. From thorough pre-operational checks to proper operational procedures, meticulous maintenance, and compliance with standards, each step is critical for safety and performance.

Tsurumi Pump provides reliable solutions and following their safety practices extends pump life and protects operators. Prioritise safety in every aspect of pump operation and consult Tsurumi Pump for expert advice and support to ensure efficient and secure operations.