Overview

At underground mine sites, staff are retained to ensure the safety and upkeep of the mine, regardless of its size. Their responsibilities include managing water levels to prevent flooding, addressing water seepage in the tunnels, and maintaining the structural integrity of the mine.

A recent example of this occurred at an underground coal mine in NSW, which requires effective dewatering, prompted the installation of a new submersible dewatering pump to manage water levels in several mine shafts.

Tsurumi's Approach

On this occasion, one of our NSW distributors, All Pumps, collaborated with the end user to design a customized solution and select a suitable submersible pump for the application. The project required a high-head pump capable of operating in a horizontal position. With input from Tsurumi’s technical experts, the Tsurumi LH4110W was chosen. Although this model is designed with two cable entries, the customer required single cable entry and All Pumps successfully provided a custom solution. Additionally, they constructed a steel frame to secure the pump, enhancing its portability and versatility for the mine.

Results & Benefits

The selected pump model, Tsurumi’s LH4110W, is equipped with Miniature Thermal Protectors that safeguard the pump from overheating due to dry-running. These protectors use a bimetal strip that responds to excessive heat by triggering the control panel to shut off the power supply. This feature helps protect the pump from internal damage, extending its lifespan, minimizing operational downtime, and reducing maintenance costs. Additionally, this safety mechanism allows the pump to operate without requiring constant staff supervision.

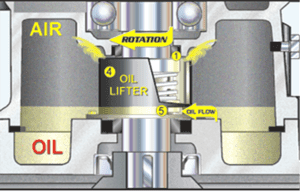

Furthermore, Tsurumi pumps are equipped with the innovative oil lifter technology, which ensures consistent lubrication and cooling of the mechanical seal faces, even at just one-third of the normal oil level. This design guarantees continuous lubrication regardless of the pump’s orientation. In this case the pump was installed and operates horizontally, a feature that competitors’ pumps lack due to their internal designs, which prevents proper lubrication of the mechanical seals in non-vertical positions.

Conclusion

The system setup requires less ongoing maintenance, staff supervision and easier portability to other areas within the underground mine. The mine has expressed great satisfaction with the Tsurumi submersible pump, highlighting the LH’s reliability and performance in a horizontal installation and the effectiveness of the Tsurumi’s original design oil lifter.

The system setup requires less ongoing maintenance, staff supervision and easier portability to other areas within the underground mine. The mine has expressed great satisfaction with the Tsurumi submersible pump, highlighting the LH’s reliability and performance in a horizontal installation and the effectiveness of the Tsurumi’s original design oil lifter.

Learn more about the submersible LH series pump.